SC(B) series epoxy resin dry type transformer is flame-retardant, fire-proof, explosion-proof, maintenance free, pollution-free, small in size, because the winding is encapsulated, and can be directly installed in the load center. At the same time, the scientific and reasonable design and casting process make the product have less partial discharge, lower noise and stronger heat dissipation capacity. Under the condition of forced air cooling, it can operate for a long time under 125% rated load. It is equipped with an intelligent temperature controller, which has the functions of fault alarm, overtemperature alarm, overtemperature trip and black box. It is connected with the computer through RS485 serial interface and can be monitored centrally and controlled. Because of the above characteristics, the dry type transformer is widely used in power transmission systems, such as hotels, restaurants, airports, high-rise buildings, commercial centers, residential areas and other important places, as well as subway, smelter, ship, offshore drilling and platform and other places with bad environment.

IEC60076-1:2011 Power transformers - Part 1: General

IEC60076-11:2018 Power transformers - Part 11: Dry-type transformers

Ambient Temperature: No more than +40℃, No less than -25℃, The monthly average temperature is no more than +30℃, The yearly average temperature is no more than +20℃.

Altitude: No more than 1000m.

The power supply voltage's wave is similar to a sine wave.

Three-phase power supply voltage is approximately symmetrical.

The relative humidity of the surrounding air should be less than 93%. There should be no water droplets on the coil surface.

Installation Site: Indoor or outdoor.

The high voltage winding is made of enameled copper wire or film wrapped copper wire, and the low voltage winding is made of copper foil. The high voltage winding is filled with glass fiber felt. In the vacuum state, the epoxy resin without filler is used for pouring, which forms a solid whole after curing, with high mechanical strength, small partial discharge and high reliability.

Flame retardant, explosion-proof, no environmental pollution, environmental protection. It can be installed in the load center.

The core material is made of high quality cold-rolled oriented silicon steel sheet with full inclined seam laminated structure.

The coil does not absorb moisture, and the core and clamp are treated by special process, which can operate in high relative humidity and other harsh environments. Intermittent operation without dehumidification treatment.

High resistance to short circuits, lightning impulse and overload.

Thin resin insulation layer inside and outside the coil, good heat dissipation performance.

Low loss, good power saving effect, economical operation and maintenance free.

Small volume, light weight, small floor space and convenient installation.

1.SCB11-30-2500/10kV Three Phase Epoxy Resin Cast Dry Type Power Transformer

| Rated Capacity (kVA) |

High Voltage (kV) |

Tapping range

|

Low voltage(kV)

|

Vector Group |

No-load Loss (W) |

Load Loss (W) |

No-Ioad

current

(%)

|

Impedance

voltage

(%)

|

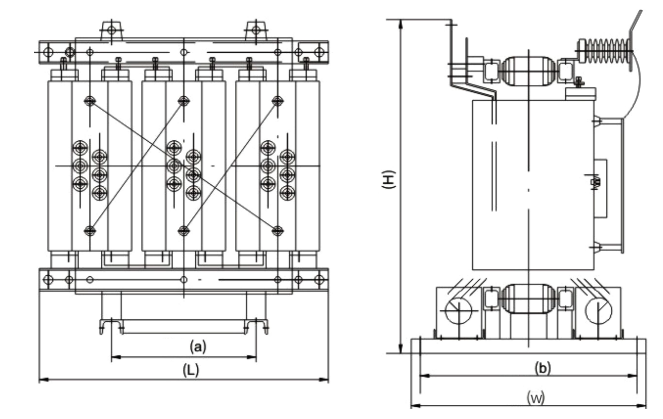

Enclosure Enclosure Dimensions (mm)L*W*H |

Weight

(kg)

|

| 30 |

6

6.3

6.6

10

10.5

11

|

±2.5%

±5%

|

0.4

|

Dyn11

|

170 |

710

|

2.3

|

4.0 |

955×750×840

|

270

|

| 50 |

240

|

1000

|

2.2

|

970×750×860

|

340

|

|||||

| 80 | 330 |

1380

|

1.7

|

1015×750×925

|

460

|

|||||

| 100 |

360

|

1570

|

1.7

|

1030×750×960

|

530

|

|||||

| 125 | 420 |

1850

|

1.5 |

1060×750×1000

|

605

|

|||||

| 160 |

480

|

2130

|

1.5

|

1090×900×1045

|

730

|

|||||

| 200 |

±2×2.5%

±5%

|

550 |

2530

|

1.3

|

1105×900×1080

|

825

|

||||

| 250 | 640 |

2760

|

1.3

|

1180×900×1125

|

1010

|

|||||

| 315 |

790

|

3470

|

1.1

|

1225×900×1140

|

1165

|

|||||

| 400 | 880 |

3990

|

1.1

|

1330×900×1195

|

1490

|

|||||

| 500 | 1040 |

4880

|

1.1

|

1345×900×1255

|

1650

|

|||||

| 630 |

1200

|

5880

|

0.9

|

1540×1150×1175

|

1915

|

|||||

| 630 |

1170

|

5960

|

0.9

|

6.0 |

1540×1150×1175

|

1915

|

||||

| 800 |

1360

|

6960

|

0.9

|

1600×1150×1220

|

2305

|

|||||

| 1000 |

1590

|

8130

|

0.9

|

1645×1150×1285

|

2690

|

|||||

| 1250 |

1880

|

9690

|

0.9

|

1705×1150×1345

|

3225

|

|||||

| 1600 | 2200 |

11700

|

0.9

|

1765×1150×1405

|

3805

|

|||||

| 2000 |

2740

|

14400

|

0.7

|

1840×1150×1475

|

4435

|

|||||

| 2500 | 3240 |

17100

|

0.7

|

1900×1150×1560

|

5300

|

|||||

| 1600 | 2200 |

12900

|

0.9 | 8.0 |

1765×1150×1405

|

3805

|

||||

| 2000 | 2740 |

15900

|

0.7

|

1840×1150×1475

|

4435

|

|||||

| 2500 | 3240 |

18800

|

0.7

|

1900×1150×1560

|

5300

|

2. SCB12-30-2500/10kV Three Phase Epoxy Resin Cast Dry Type Power Transformer

| Rated Capacity (kVA) |

High Voltage (kV) |

Tapping range

|

Low voltage(kV)

|

Vector Group |

No-load Loss (W) |

Load Loss (W) |

No-Ioad

current

(%)

|

Impedance

voltage

(%)

|

Enclosure Enclosure Dimensions (mm)L*W*H |

Weight

(kg)

|

| 30 |

6

6.3

6.6

10

10.5

11

|

±2.5%

±5%

|

0.4

|

Dyn11

|

150

|

710

|

2.3

|

4.0 |

955×750×840

|

270

|

| 50 |

215

|

1000

|

2.2

|

970×750×860

|

340

|

|||||

| 80 |

295

|

1380

|

1.7

|

1015×750×925

|

460

|

|||||

| 100 |

320

|

1570

|

1.7

|

1030×750×960

|

530

|

|||||

| 125 |

375

|

1850

|

1.5 |

1060×750×1000

|

605

|

|||||

| 160 |

430

|

2130

|

1.5

|

1090×900×1045

|

730

|

|||||

| 200 |

±2×2.5%

±5%

|

495

|

2530

|

1.3

|

1105×900×1080

|

825

|

||||

| 250 |

575

|

2760

|

1.3

|

1180×900×1125

|

1010

|

|||||

| 315 |

705

|

3470

|

1.1

|

1225×900×1140

|

1165

|

|||||

| 400 |

785

|

3990

|

1.1

|

1330×900×1195

|

1490

|

|||||

| 500 |

930

|

4880

|

1.1

|

1345×900×1255

|

1650

|

|||||

| 630 |

1070

|

5880

|

0.9

|

1540×1150×1175

|

1915

|

|||||

| 630 |

1040

|

5960

|

0.9

|

6.0 |

1540×1150×1175

|

1915

|

||||

| 800 |

1210

|

6960

|

0.9

|

1600×1150×1220

|

2305

|

|||||

| 1000 |

1410

|

8130

|

0.9

|

1645×1150×1285

|

2690

|

|||||

| 1250 |

1670

|

9690

|

0.9

|

1705×1150×1345

|

3225

|

|||||

| 1600 |

1960

|

11700

|

0.9

|

1765×1150×1405

|

3805

|

|||||

| 2000 |

2440

|

14400

|

0.7

|

1840×1150×1475

|

4435

|

|||||

| 2500 |

2880

|

17100

|

0.7

|

1900×1150×1560

|

5300

|

|||||

| 1600 |

1960

|

12900

|

0.9 | 8.0 |

1765×1150×1405

|

3805

|

||||

| 2000 |

2440

|

15900

|

0.7

|

1840×1150×1475

|

4435

|

|||||

| 2500 |

2880

|

18800

|

0.7

|

1900×1150×1560

|

5300

|

3. SCB13-30-2500/10kV Three Phase Epoxy Resin Cast Dry Type Power Transformer

| Rated Capacity (kVA) |

High Voltage (kV) |

Tapping range

|

Low voltage(kV)

|

Vector Group |

No-load Loss (W) |

Load Loss (W) |

No-Ioad

current

(%)

|

Impedance

voltage

(%)

|

Enclosure Enclosure Dimensions (mm)L*W*H |

Weight

(kg)

|

| 30 |

6

6.3

6.6

10

10.5

11

|

±2.5%

±5%

|

0.4

|

Dyn11

|

135

|

640

|

2.3

|

4.0 |

955×750×840

|

270

|

| 50 | 195 |

900

|

2.2

|

970×750×860

|

340

|

|||||

| 80 |

265

|

1240

|

1.7

|

1015×750×925

|

460

|

|||||

| 100 | 290 |

1410

|

1.7

|

1060×750×960

|

560

|

|||||

| 125 | 340 |

1660

|

1.5 |

1075×750×1000

|

630

|

|||||

| 160 | 385 |

1910

|

1.5

|

1105×900×104

|

770

|

|||||

| 200 |

±2×2.5%

±5%

|

445 |

2270

|

1.3

|

1120×900×1105

|

875

|

||||

| 250 |

515

|

2480

|

1.3

|

1195×900×1125

|

1055

|

|||||

| 315 | 635 |

3120

|

1.1

|

1555×1150×1175

|

1190

|

|||||

| 400 | 705 |

3590

|

1.1

|

1225×900×1140

|

1500

|

|||||

| 500 | 835 |

4390

|

1.1

|

1315×900×1190

|

1700

|

|||||

| 630 | 965 |

5290

|

0.9

|

1345×900×1265

|

1985

|

|||||

| 630 | 935 |

5360

|

0.9

|

6.0 |

1555×1150×1175

|

1985

|

||||

| 800 |

1090

|

6260

|

0.9

|

1600×1150×1220

|

2360

|

|||||

| 1000 |

1270

|

7310

|

0.9

|

1660×1150×1285

|

2775

|

|||||

| 1250 |

1500

|

8720

|

0.9

|

1720×1150×1350

|

3310

|

|||||

| 1600 |

1760

|

10500

|

0.9

|

1780×1150×1405

|

3940

|

|||||

| 2000 |

2190

|

13000

|

0.7

|

1840×1150×1475

|

4595

|

|||||

| 2500 |

2590

|

15400

|

0.7

|

1900×1150×1565

|

5495

|

|||||

| 1600 |

1760

|

11600

|

0.9 | 8.0 |

1780×1150×1405

|

3940

|

||||

| 2000 |

2190

|

14300

|

0.7

|

1840×1150×1475

|

4595

|

|||||

| 2500 |

2590

|

17000

|

0.7

|

1900×1150×1565

|

5495

|

Send us a message if you have any questions or request a quote.Our experts will give you a reply within 24 hours

and help youselect the right valve you want.